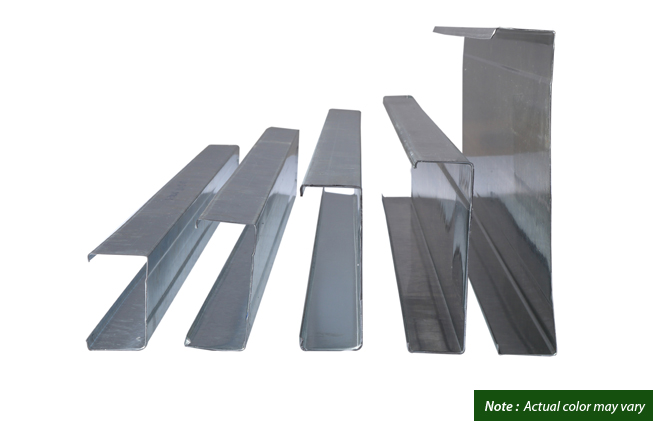

In the roofing industry, C purlins play a crucial role in providing structural support to roofing systems. C purlins are long, horizontal beams with a cross-section resembling the letter “C.” These components are made from various materials, including steel, and are widely used in the construction of roofs, walls, and structural frameworks. Their ability to support various roofing materials and withstand environmental factors makes them a key component in the design and construction of durable and reliable roofing systems. In this blog article, we’ll learn more about C purlin sizing.

Types of Loads on Structures

Before talking more about the standard length of C purlins or the standard size of C purlins in the Philippines, we need to talk about the types of loads on structures. Understanding them is crucial for designing and constructing buildings that can withstand different forces.

- Dead Loads

Dead loads refer to the static or constant loads that a structure must support. These include the weight of the building materials, the structure itself, and any permanent fixtures or components. In the context of roofing, dead loads encompass the weight of the roof covering, support beams, purlins, and other permanent elements. - Live Loads

Live loads are dynamic or moving loads that a structure experiences during its intended use. These loads can vary and include the weight of people, furniture, equipment, and other temporary or transient items. For roofing, live loads may consist of maintenance personnel or HVAC equipment. - Wind Loads

Wind loads refer to the forces exerted by wind on a structure, especially its exposed surfaces. In roofing design, wind loads are a significant consideration, particularly in regions susceptible to strong winds or frequent storms. Factors such as the shape and height of the structure, as well as the type of roofing materials, influence how the wind affects the roof. - Seismic Loads

Seismic loads are forces generated by earthquakes or ground movements. In earthquake-prone areas, engineers must consider the potential impact of seismic activity on the structure, including the roofing system. Seismic loads can induce lateral forces and vibrations, and structures need to be designed to resist these movements and remain structurally sound during an earthquake. Read this for more details on how to build an earthquake-resistant structure: https://www.ugc.ph/news/5-ways-to-build-an-earthquake-resistant-structure/.

The Role of C Purlin Sizes in Managing Loads

C purlins, when sized correctly, play a pivotal role in managing loads on roofing structures. From ensuring even weight distribution to preventing overloading and enhancing weather resilience, the appropriate sizing of C purlins contributes to the overall durability and safety of roofing systems in the face of diverse environmental challenges.

- Weight Distribution

C purlins, when appropriately sized and spaced, help evenly distribute dead loads and live loads across the roof. Proper weight distribution ensures that the structural elements, including the purlins themselves, bear loads within their specified capacity, minimizing the risk of structural failure. - Avoiding Overloading

Overloading occurs when the cumulative loads on the structure exceed its designed capacity, leading to potential structural damage. By accurately determining the required size and spacing of C purlins, engineers can prevent overloading and ensure that the roofing structure can withstand the stresses imposed by dead, live, wind, and seismic loads. This is particularly critical in regions with varying weather conditions. - Weather Resilience

The size and spacing of C purlins are integral to the weather resilience of a roofing system. In areas prone to adverse weather conditions such as heavy rain or strong winds, appropriately sized purlins contribute to the structural stability of the roof. They help distribute the added weight of accumulated water, for example, or resist uplift forces caused by strong winds, enhancing the overall resilience of the roofing system against the elements.

The Safety Implications

Ensuring that C purlins are adequately sized for the loads they’ll bear is a fundamental aspect of construction safety. The right sizing not only supports the structural integrity of the roofing system but also mitigates various risks associated with improper load management.

- Structural Collapses

Inadequate sizing of C purlins can significantly increase the risk of structural collapses. The failure to support dead and live loads, as well as potential wind and seismic forces, may lead to catastrophic consequences. Properly sized C purlins, in accordance with engineering calculations and safety standards, prevent the risk of structural failures that could compromise the safety of occupants and the integrity of an entire building. - Long-Term Wear

C purlins that are undersized may experience excessive stress over time, leading to long-term wear and structural deterioration. Continuous exposure to loads beyond their designed capacity can result in fatigue, deformation, and, ultimately, failure. Adequately sized C purlins not only ensure the immediate safety of the structure but also contribute to its long-term durability, reducing the likelihood of wear-related issues and the need for premature maintenance or replacement. - Inefficient Energy Consumption

The energy efficiency of a building is closely tied to its structural integrity. Improperly sized C purlins can contribute to inefficient energy consumption by compromising the effectiveness of insulation and ventilation systems. Gaps or structural deformities in the roofing system may lead to heat loss or gain, impacting the building’s overall energy efficiency. Well-sized C purlins contribute to a tightly sealed and insulated roofing envelope, supporting the efficient use of energy for heating, cooling, and overall climate control within the structure.

Consultation is Key

Given the safety implications, it’s always advisable to consult with structural engineers or experts when selecting C purlin sizes. Structural engineers possess the expertise to perform precise calculations based on factors such as building design, geographical location, anticipated loads, and material specifications. Their knowledge ensures that the selected C purlin sizes align with safety standards and regulatory requirements.

If you want to talk to someone about C purlins sizes in the Philippines, Union Galvasteel Corporation is here for you. UGC stands out as a valuable partner in the construction process, offering not only quality roofing materials but also expert guidance in selecting the right C purlin sizes. The collaboration between construction professionals and UGC can enhance the safety and efficiency of roofing projects. By emphasizing the importance of consultation, especially with structural engineers, and highlighting the support that UGC provides in choosing the right c purlin dimensions and c purlins length in the Philippines, the construction industry can ensure that roofing systems are not only structurally sound but also optimized for long-term performance and safety.

For over 60 years, UGC has been a market leader in the manufacturing and distributing of pre-painted and other galvanized roofing in the Philippines. We have the industry’s largest and most diversified distribution network, with warehouses and sales offices in strategic locations throughout the country. For a full catalog of light steel frames and other roof products, get in touch with us via our website and Facebook or call these numbers for assistance: (02) 8520-8822-23; 8520-8831; (049) 545-0084 to 86 or 09175033965 (Globe) and 09190032303 (Smart).