All of us want our homes to look the best and reflect our personalities. That’s why we add elements we like or express our style through the colors we use. Aside from walls, you may also want to paint your roof in a certain color. If your roof is made of galvanized steel, how should you paint it? Let’s find out how to paint galvanized roofing properly.

Components of Galvanized Steel

Galvanized steel is formed by applying a zinc coating to the surface of the steel. This coating prevents rust. The coating is done in several ways. A common way is dipping the metal in molten zinc until it gets enough coverage. A simple analogy for this would be a piece of chicken being breaded before frying.

Another method is called “electro galvanizing.” This method makes use of ions in the metal and maximizes their potential to add a thin layer of zinc. This is usually done for steel that will be treated with decorative coating after galvanizing.

There is also what we call thermal fusion galvanizing or sherardizing, which makes use of a zinc diffusion coating. In this process, zinc coating is applied through a sealed rotating drum. By tumbling the metal and zinc powder together at around 300 degrees Celsius, a zinc alloy is produced by the end of the process.

Components of Paint

Meanwhile, paint usually has three components: the binder, the pigment, and the thinner. When the paint is oil-based, it has a binder that can either be made from linseed (a natural oil) or alkyd (a synthetic oil). A synthetic-based oil is cheaper but works better, but regardless of the type of oil-based paints, both are durable and can withstand a lot of wear and tear.

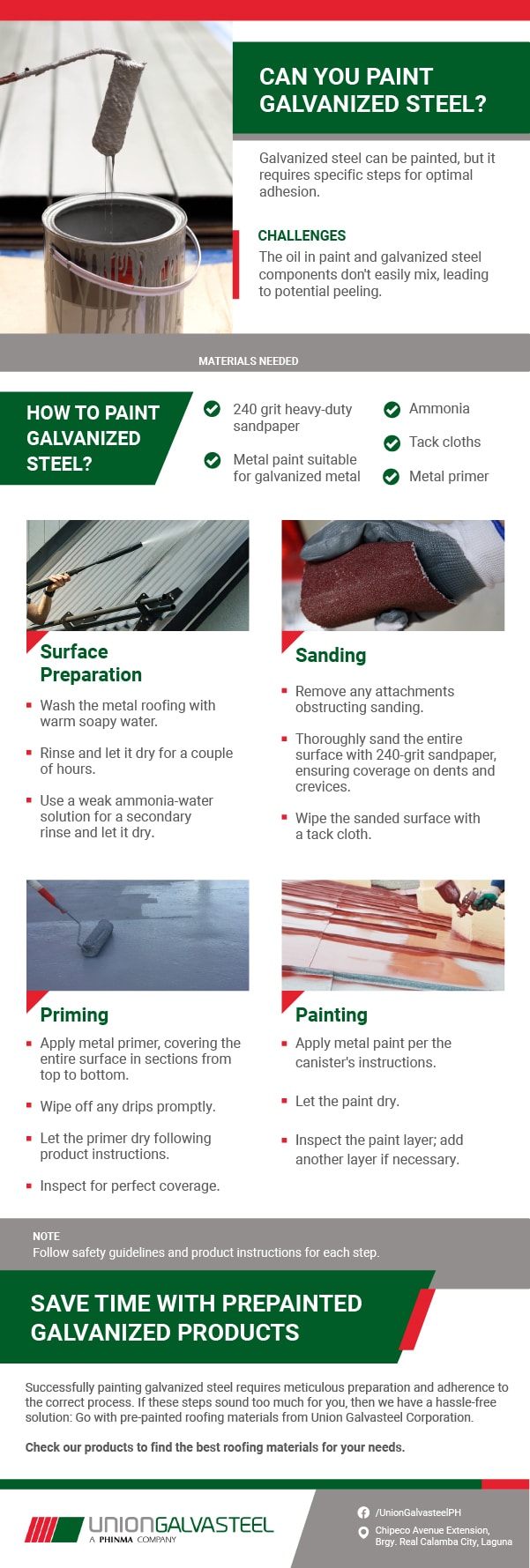

Can you paint galvanized steel?

The short answer to this question is yes, but there are more layers to it. To fully understand this, let’s discuss the components of galvanized steel and paint.

The oil in the paint and the components in galvanized steel do not mix easily. It’s like trying to mix water with oil. Yes, the paint may adhere to galvanized iron, but only for a while. Eventually, the paint will peel or fall off. This is due to saponification, wherein a soapy film is formed upon the reaction of the binder of the paint with the coating of zinc that protects the galvanized steel from rust and corrosion. However, with appropriate treatments beforehand, you can successfully paint galvanized steel roofing.

How to Paint Galvanized Steel

To ensure that paint remains on galvanized steel, start by gathering the following:

- 240 grit heavy-duty sandpaper

- Ammonia

- Tack cloths

- Metal primer

- Metal paint with the same brand as the primer (make sure it works for galvanized metal)

Once all the materials above are on hand, follow these steps:

- Wash the metal roofing with warm soapy water.

- Rinse and let it dry for a couple of hours.

- Create a weak ammonia-water solution and use it to rinse the metal. Let it dry for a couple of hours again.

- Prepare the material for sanding by removing any attachments or handles that may become an obstruction when sanding.

- Thoroughly sand the entire surface area of the metal with the 240-grit sandpaper, making sure to get dents and crevices on the metal.

- Wipe the sanded surface with a tack cloth.

- Apply the metal primer. Make sure you cover the entire surface area, working in sections from top to bottom.

- If drips start to manifest, wipe them as soon as possible.

- Let the primer dry per product instructions.

- Once dry, inspect if the surface is perfectly covered by the primer.

- Apply the metal paint following the instructions in the canister.

- Let the paint dry.

- Inspect the layer of paint on the surface once fully dried. Add another layer of paint if necessary.

Save Time with a Prepainted Galvanized Products

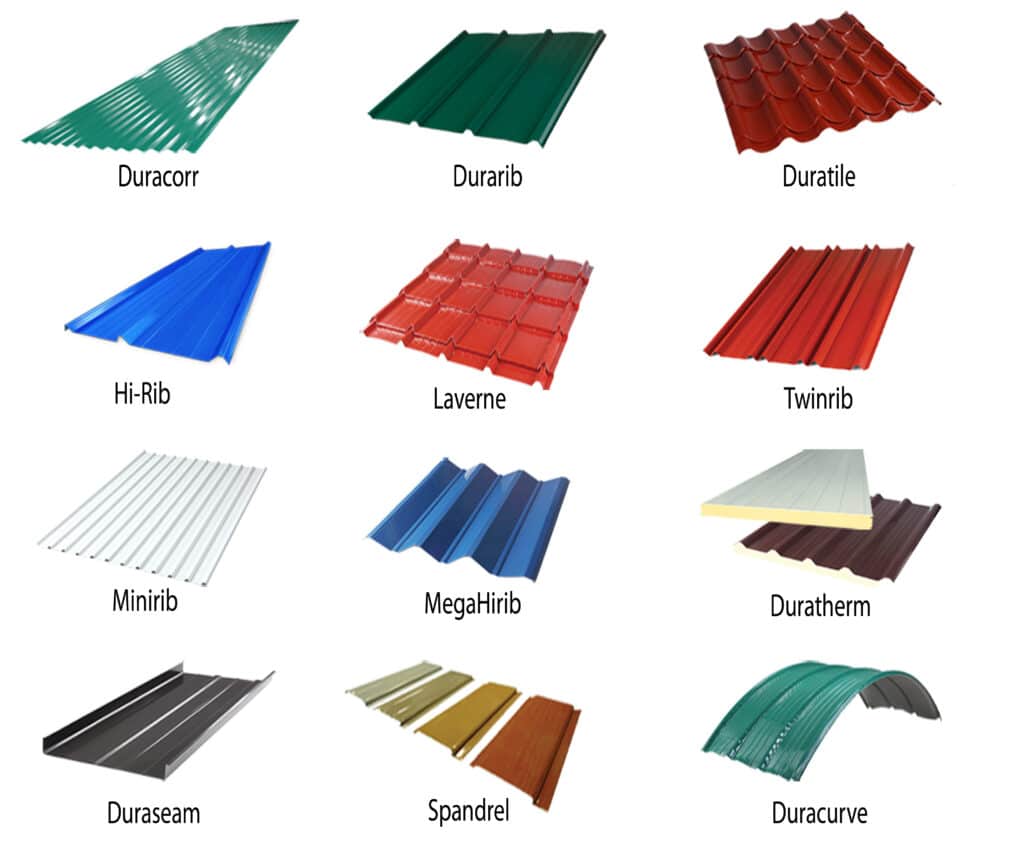

If these steps sound too much for you, then we have a hassle-free solution: Go with pre-painted roofing materials from Union Galvasteel Corporation instead. These products come in different colors. UGC can even create special colors for you upon request. You don’t need to buy galvanized roof paint.

A popular UGC roofing is Duracorr, which has a classic design. Its sinusoidal corrugation makes it withstand heavy loads or weight and prevents further dents. Durarib is another product we recommend, especially because our country experiences a lot of rain. Its deep corrugation design allows it to carry a large volume of rainwater. Duratwin also provides leak protection and offers durability, making it ideal for industrial buildings, housing projects, and warehouses.

For gymnasiums, warehouses, and almost all flat roof structures, UGC’s Hi Rib roofs are highly recommended. With their high rib height at 50 mm, they prevent leaks during a heavy downpour. For industrial plants with long spans and very steep slopes, we recommend our Mega Hi-Rib roofs. These roof materials have a deep corrugation design capable of carrying a large volume of rainwater. Meanwhile, its high rib height and non-flat surface provide extra strength.

If you are looking for a roofing contractor in the Philippines or have questions about roof price in the Philippines, then UGC is here for you. For over 60 years, UGC has been a market leader in the manufacturing and distributing of pre-painted and other galvanized roofing in the Philippines. We have the industry’s largest and most diversified distribution network, with warehouses and sales offices in strategic locations throughout the country. For roofing products and services, get in touch with us via our website and Facebook or call these numbers for assistance: (02) 8520-8822-23; 8520-8831; (049) 545-0084 to 86 or 09175033965 (Globe) and 09190032303 (Smart).